Majority of industrial motors are induction motors That's why Its become crucial to study every aspect of induction motor. Like any other machine, Induction motors also have name plate which describes important credentials.

Whatever the step we are going to take whether we are going for motor connections or finding a motor fault. The first & most important step is reading a NAME PLATE.

The list of parameters for induction motor is very long, Its not possible to mention all the parameters so few of them which are most important; are provided on name plate.

In this post, we are going to discuss the Name plate of Induction Motor.

In this post, we are going to discuss the Name plate of Induction Motor.

NAME PLATE OF INDUCTION MOTOR

|

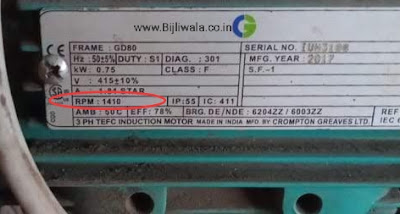

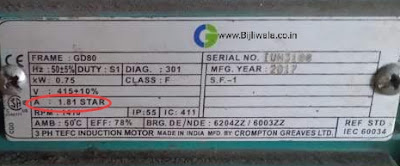

| Induction Motor's nameplates -1 |

Manufacturer name & Serial number, Motor Rating (kW Or hp), speed, voltage, frequency, Rated current, duty cycle, Motor Connections, efficiency, power factor, Bearing size, ambient temperature, torque, manufacturing date, insulation class, frame, weight of Motor, cooling system, Ingress protection etc.

1. Manufacturer name & LOGO

When we see a motor name plate, our first sight drop on Logo or Name of the Manufacturer.

|

| Name plate of 0.75kw Crompton Greaves 3phase Induction Motor -2 |

Top companies are in every field. These companies set a benchmark for other companies behind them. These behind companies try to follow the benchmark set by the top companies. Likewise In India, Electrical motor manufacturers Siemens, Kirloskar, ABB, Crompton Greaves etc. are at top in motor manufacturing. These companies spend lot of money on research & testing. The product of top companies are costly but We feel safe and reliable when we see a well known label of these companies.

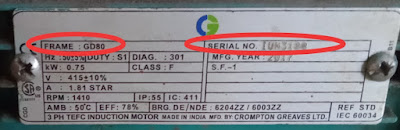

2. Serial Number

Serial number of a motor is like a unique identification number(UIN) which makes the motor unique & only individual with that particular number from manufacturing company.

An image shown above contains the serial number; been circled red.

3. Frame Number

Motor's frame number is a standard which tells about motor's mounting type & its all around measurements, Its shaft, mounting hole & distance in between them. Since it is not possible to mention all the measurements on single name plate that's why a standard number is given to a particular motor frame.

It is very helpful, we can replace a motor of same rating with a motor of another manufacturer if frame number & Rating is same. These frame standard build by NEMA(National Electrical Manufacturers Association).

4. Motor Rating (KW OR HP)

Motor Rating implies motor's rated power which is a very important parameter. It could be given in hp or in KW or in both.

|

| Name plate of induction motor with power rating 0.75kw/1hp -3 |

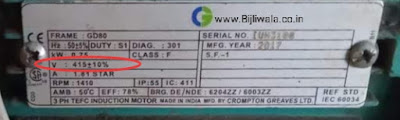

5.Voltage

Motors are designed for particular voltage range at which motor operate at optimum efficiency & achieve its maximum useful life. In India 3 phase working voltage is 400V± 6% that's why we need 3 phase induction motors designed for 400Volts in INDIA.

In an image below Working voltage of 3 phase induction motor is 415±10% which means working voltage shall be between 373 to 456Volts.

|

| Name plate of Induction motor with working voltage of 415±10% Volts -4 |

6. Frequency

In India, frequency standard is 50hz±3%. In an image Supply frequency for 3 phase induction motor is 50±5% which means frequency range must be in between 47.5Hz to 52.5Hz.

It is an important parameter Because speed is frequency dependent in Induction motors which is briefly explained next in the term SPEED.

7. Speed(RPM)

Speed of induction motor described in RPM (Rotation per minute). Generally, Induction motor are available in 2800,1440,960 & 750 RPM at 50hz frequency.

"Speed of induction motor changes with frequency."

Synchronous speed, Ns= [(120*frequency) / poles]

- CASE1. Poles=4, frequency=50Hz, Ns=[(120*50)/4]=1500rpm

- CASE2. Poles=4, frequency=60Hz, Ns=[(120*60)/4]=1800rpm

Which means speed increases as frequency increases.

BUT Induction motor's speed is not Synchronous speed. In Induction motor, Magnetic field which is generated by stator actually rotates at synchronous speed & rotor tries to catch that magnetic field.

In induction motor, Rotor speed is slower than synchronous speed. The difference in synchronous speed & rotor actual speed is known as slip(s) which in general explained in percentage. Slip=[(Ns-Nr)/Ns]*100

In an Image-6

At rotor speed(Nr) 1410 rpm & at Synchronous speed(Ns) 1500 rpm

Slip=[(1500-1410)/1500]*100=6%

Since Induction motors don't rotates at synchronous speed that's why induction motors are known as Asynchronous motors. The impact of supply frequency also the same on rotor speed as on synchronous speed.

8. Rated Current

Rated current shows final current limit up to which motor can work continuously safely. Under the rated current motor's noise, vibration & temperature remains in permissible limit. Rated current of the motor depend upon the power rating, voltage & Type of power supply(No. of phases).

Load current more than rated current produces excess stress on the winding which deteriorate the useful life of the motor. Even excess current more than a limit; can damage the winding insulation permanently.

|

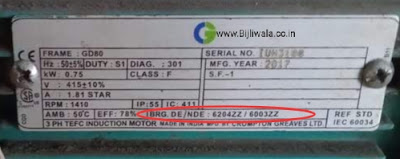

| Name plate of Induction motor| Rated current 1.81 Amps-7 |

9. Duty cycle

Duty cycle defines which type of working periods induction motor designed for.Since it is not necessary that all the motors running continuously for long period of time. There is operation of starting, NO load running, full load running, Breaking & Rest period of Induction Motor. These operations are viewed by how they affect the motor temperature in order to determine if the selected motor correct for the application.

According to application requirements,

- Some applications have long run time period such that motor reaches to its final temperature equilibrium state. Such duty known as continuous duty(S1).

- Some applications have short run period than there is rest period, such that motor's temperature reaches to ambient temperature after reaching its final equilibrium temperature. Such duty known as short time duty (S2).

- Some application have cyclic continuous state such that motor runs & stops continuously. Its lowest temperature doesn't reach to ambient temperature. Such duty known as Intermittent periodic duty (S3).

- Some applications have continuous run period, break period & rest period such duty known as continuous duty with breaking(S4).

10. Efficiency

Efficiency which is expressed in percentage explain how efficiently motor can consume Electrical power. It is the ratio of mechanical power output to electrical power input.

|

| Name plate of Induction motor| Efficiency 78% |

11. Power factor

Induction motors are inductive loads & their normal power factor range lies in between 0.70-0.9(lagging).

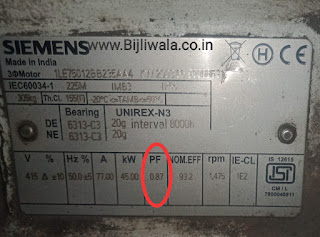

|

| Name plate induction motor| 0.87 power factor |

12. Bearing size

A few motor manufacturers mentions bearing sizes on name plate. There is benefit of bearing size mentioning if bearing got damaged we can arrange the bearings by knowing the bearing numbers without opening the motor covers.

|

| Name plate of induction motor marked with both the bearing numbers DE(driving end) & NDE(non driving end) |

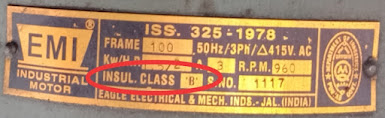

13. Insulation class

Insulation class refers to maximum temperature which motor insulation can withstand.

There are different classes of insulation in which four classes are the major one Which are shown in a tabular form:

There are different classes of insulation in which four classes are the major one Which are shown in a tabular form:

|

| Insulation classes defined by NEMA |

All the insulation classes are considered at ambient temperature of 40°C. It is very important to consider Insulation class in motor selection because wrong insulation selection leads to sudden deterioration of the motor. The place where motor is going to be installed, ambient temperature & type of pollution around the motor, all the parameters are important to consider.

14. Torque

Torque is the rotational force produced by the rotor. SI unit of torque is newton-meter. In some cases torque is mentioned in kg-m .

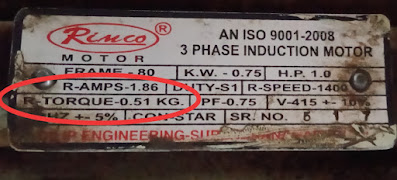

|

| Torque rating on 3-phase Induction Motor |

15. Cooling system

Normally we have seen, A cooling fan is mounted on the shaft at the back of motor. But there are many more different cooling methods. In big size motors, an auxiliary fans or water pumps are provide for motor cooling. To mention the cooling method, a number system is used Which describes the type of cooling.

For example

IC411 -(TEFC) Totally enclosed fan cooled

In this motor is fully closed, a fan is mounted on shaft at non driving end which passes air from the motor surface.

IC411 -(TEFC) Totally enclosed fan cooled

In this motor is fully closed, a fan is mounted on shaft at non driving end which passes air from the motor surface.

|

| Induction Motor's nameplate depicting type of cooling system of motor |

16. Ingress protection

Industrial environment is hard in some cases it is very hard. Iron dust, moisture, vibrations, corrosive environment put bad impact on motor's winding.

There is danger of ingress of dust particle & liquid material. To protect the motor from both of these, motors are manufactured accordingly. Motors are manufactured according to the level of protection from both of two, liquid & solid particles.

The ingress protection of motor is denoted in a combination of numbers & alphabets.

For example

IP44- IP stands for ingress protection. Units digit is given for the protection from the liquid & Tens digit given for the protection from the solid particles.

Tens digit

If given tens digit is 1, It provides protection from object greater than 50 mm.

If given tens digit is 4, It provides protection from object greater than1mm. At 6, it is dirt proof.

Unit digit

if given unit digit is 1, It provides protection from water droplets falling downward for 10 Minutes.

if given unit digit is 8, It provides protection from water immersion for long period.

|

| Name plate of induction motor| Ingress protection 55 |

17. Manufacturing date & Weight of the motor

Manufacturing date & weight of the motor also mentioned on the name plate.

Hope this article will be helpful. If you have any query or suggestion please do comments!

Tags:

Induction motor